In the era of Industrial Revolution 4.0, digital twin technology has generated a lot of excitement, with its applications and cases being investigated and implemented in a variety of industries. From preventing a disaster on the 80-year-old Stav bridge in Norway to utilizing it as a real-time rocket simulation by Nasa in 2010.

Let us gain a comprehensive grasp of digital twin technology.

What is Digital twin technology?

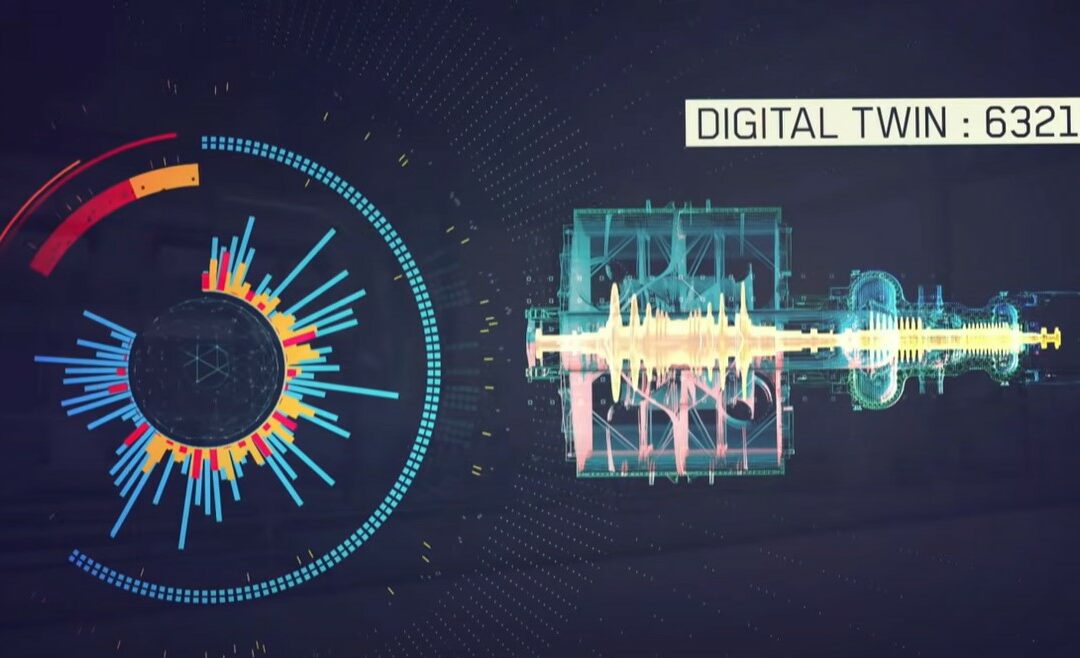

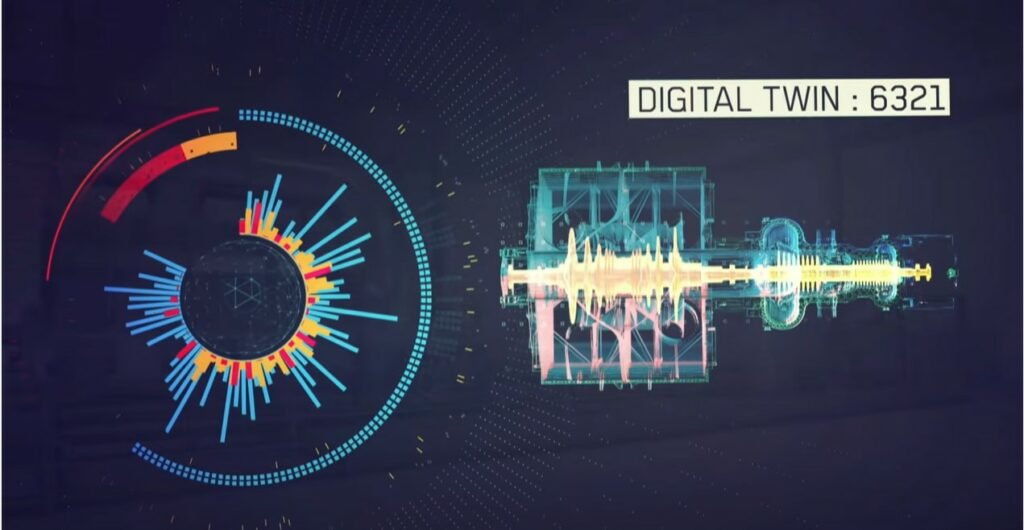

As the name implies, it is a “twin.” By “twin,” we mean the twin of a real-world counterpart operating and simulating the exact same thing. The application and use cases vary depending on the information needed.

What is the working of digital twin technology?

This technique is based on mathematical data and code sets. By comparing digital twin technology to a game, we can understand how it works; the only difference is that the conditions and details supplied to the program are exactly the same as in real life. A properly functional model necessitates adequate IoT application.

What is a model in digital twin technology?

In this technique, a model may represent anything from a manufacturing unit to a product, a city, a structure, and so on.

What data factors is digital twin technology capable of providing?

It obtains scientific data such as structural, thermal, and so on. Any changes made to a functioning model may result in real-time data changes. A model can also generate financial, geographic, and other data by combining mathematical data with real-world examples with the combination of ML and AI the model becomes dynamic which can take historical data and calculation.

Which type of engineers are required in the creation of the model?

As of now, digital twin technology is widely used by aeronautical and mechanical engineers, but with the advancement of AI and machine learning, the digital twin requires codes for the simulation of condition, mechanical aspects to provide simulation and design data for visual inspection, and it also depends on the model whether the model involves electrical, mechanical, or civil sets of data, all of which are equally important for the perfect operation of a model.

Where it is used?

Digital has been mostly used by the manufacturing, aerospace and defence industries.

Following are the example of digital twin applications:

✴Singapore built a 3D digital model of the entire country for sustainable transportation, town. Development

✴AspenTech introduced their digital twin hybrid models, which are valuable in the domains of chemical engineering. ✴Siemens uses digital twin for its manufacturing process and development businesses

✴ The Norwegian government is adopting it for real-time inspection and safety of ageing structures such as bridges and roads.

It can also be utilized by nuclear power plants in the future to accomplish various tasks that will result in innovation and improved outcomes.

Which industry is using it?

This technology is applicable in all sectors, but the presence of this technology has been rising in Manufacturing, Healthcare, Supply chain, construction, and retail. According to Deloitte, the global market for digital twins will grow at a 38% compound annual growth rate to reach $16 billion by 2023.

In the future, the application of this technology will produce greater business and capital growth in the corporate sector.

History

- The idea of the Digital twin is penned by David Gelerneter.

- It was publicly introduced in 2002 at the Society of Manufacturing Engineers conference in Troy, Michigan

- The concept was first applied in Manufacturing.

Digital twin application explained by GE research on how they are using digital twin

Digital twin application explained by GE research on how they are using digital twin

Do you want to know how to create an innovative design ? read this article:

8 Amazing tips for creating an innovative design by Sandip Paul