Are you tired of the same old manufacturing processes that have been used for decades? Are you ready for something new, innovative, and efficient? Look no further than additive manufacturing, the future of Industry 4.0!

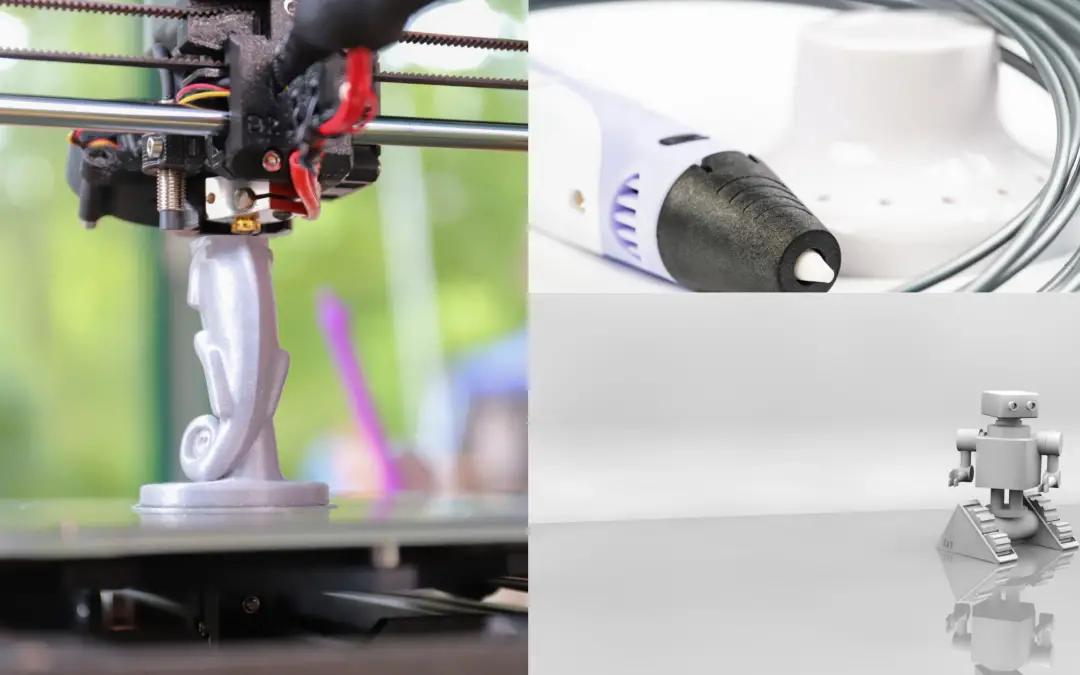

Additive manufacturing, also known as 3D printing, is a game-changing technology that is revolutionizing the way we manufacture products. Instead of traditional subtractive manufacturing methods, which involve cutting and shaping materials, additive manufacturing builds products layer by layer, using materials like plastic, metal, and even human tissue.

The benefits of additive manufacturing are numerous. For one, it allows for much more efficient use of materials, as only the necessary amount is used for each product. Additionally, it allows for the creation of complex geometries that would be impossible to achieve with traditional methods. This means that products can be designed and produced with more precision and customization than ever before.

But the advantages of additive manufacturing don’t stop there. It also has the potential to transform entire industries, particularly in the medical and construction fields. In the medical field, 3D printing is already being used to create customized prosthetics, dental implants, and even human tissue. This technology has the potential to revolutionize the way we approach healthcare, making treatments more efficient, effective, and accessible.

In the construction industry, 3D printing is being used to create entire buildings, reducing waste and speeding up construction times. This technology also allows for more intricate designs, meaning that buildings can be more aesthetically pleasing and energy-efficient.

If you’re interested in learning more about additive manufacturing, be sure to check out this informative video by ASME. It’s a fascinating look at how this technology is changing the manufacturing landscape and transforming entire industries. So why stick with the old when you can embrace the new? Additive manufacturing is the future, and it’s here to stay!

In the midst of the COVID-19 pandemic, the importance of 3D printing became more apparent than ever. With manufacturing needed in remote locations and at a rapid pace, 3D printing technology played a vital role in ensuring that critical supplies were available when and where they were needed.

As an engineer, it’s essential to have a basic understanding of 3D printing and the printing process. However, selecting the proper 3D printer and materials for your application is just as critical. That’s where the informative article by PROTOLABS comes in. The article clearly explains the different types of 3D printing technologies available, including Stereolithography (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), and more. It also covers the different materials available for each type of printing technology, allowing you to make an informed decision when selecting the right printer for your needs.

But what if you’re interested in metal 3D printing? This exciting and rapidly evolving technology offers unique advantages over traditional manufacturing methods, but it requires a different approach. That’s where the informative YouTube video on metal material science for 3D printing comes in. It offers a detailed and fascinating look at the various types of metal powders and the importance of proper handling and processing techniques. The video also covers the importance of understanding the mechanical properties of the metal used in 3D printing to ensure that the final product meets the necessary requirements.

Whether you’re interested in 3D printing for its efficiency and speed or the unique possibilities it offers for metal printing, it’s essential to stay informed and up-to-date on the latest developments in this exciting field. The resources mentioned above provide an excellent starting point for anyone looking to expand their knowledge and understanding of 3D printing. So why not dive in and discover the exciting world of 3D printing today?

Metallic 3D printing can be costly, which is why many people suggest electroplating SLA parts as a cost-effective alternative. However, to make informed decisions about the best manufacturing process for your needs, it’s crucial to have a basic understanding of mechanics and material science. As a mechanical engineer, this knowledge will give you a significant advantage in selecting the most suitable manufacturing process.

If you’re interested in learning more about 3D printing materials and their applications, the detailed blog by Formlabs is an excellent resource to start with. The blog covers the various types of 3D printing technologies and the materials used for each one, making it easier to select the best printing method for your project.

As a designer, it’s also crucial to gain practical experience in creating 3D printed parts. By understanding the practical aspects of designing, you’ll be able to apply a range of thumb rules, especially when it comes to designing snap-fit parts. For designers looking to hone their skills, a valuable resource is the book, “Designing for 3D Printing: Snap Fit Design.” It covers the fundamentals of designing snap-fit parts, providing a practical guide to help you create successful 3D printed parts that meet the required specifications.

n conclusion, understanding the different types of 3D printing technologies and their materials, as well as basic mechanics and material science principles, is crucial to making informed decisions about the manufacturing process. By gaining practical experience in designing and creating 3D printed parts, you’ll have the knowledge and skills necessary to produce successful parts that meet your needs. So why not start learning today and unlock the potential of 3D printing technology for your projects?

FUN FACT

Well 3D printing is also done in construction yaa you heard right to build houses

A post office in Benglore,india is build by 3D pritning the work was done by LARSEN & TOURBO click here to know more